The Ultimate Guide to Industrial Sandblasting: How It Works & Why You Need It

Picture this: You’ve got a piece of equipment that’s seen better days—maybe it’s covered in rust, peeling paint, or years of grime. You could spend hours scrubbing, scraping, sanding, or even crying over it (we won’t judge). Or… you could call in the big guns: industrial sandblasting.

Sandblasting is like giving your metal surfaces a high-pressure spa day—except instead of cucumber water, it gets a blast of abrasive materials to strip away all the gunk. Intrigued? Let’s dive into how sandblasting works, why it’s a game-changer, and how to do it safely.

What Is Industrial Sandblasting? (No, It’s Not a Beach Day)

At its core, sandblasting (also called abrasive blasting) is a process that uses compressed air to shoot abrasive materials at high speeds onto a surface. The goal? To clean, smooth, or even reshape it.

Originally, actual sand was used (hence the name), but these days, we’ve got better, safer options—because breathing in silica dust is not on anyone’s bucket list.

How Does it Work?

Why Sandblasting Is the MVP of Surface Prep

If it had a LinkedIn profile, its skills section would be extensive. Here’s why industries swear by it:

- Deep Cleaning Power – Removes rust, old paint, and contaminants like a boss.

- Better Paint Adhesion – Creates the perfect surface for coatings to stick.

- Restores Aesthetics – Brings new life to your old metal.

- Extends Equipment Life – Bye-bye, corrosion. Hello, longevity.

- Cost-Effective – Faster and more efficient than manual sanding, scraping, or chemical treatments.

Basically, it’s the superhero your rusty, crusty equipment deserves.

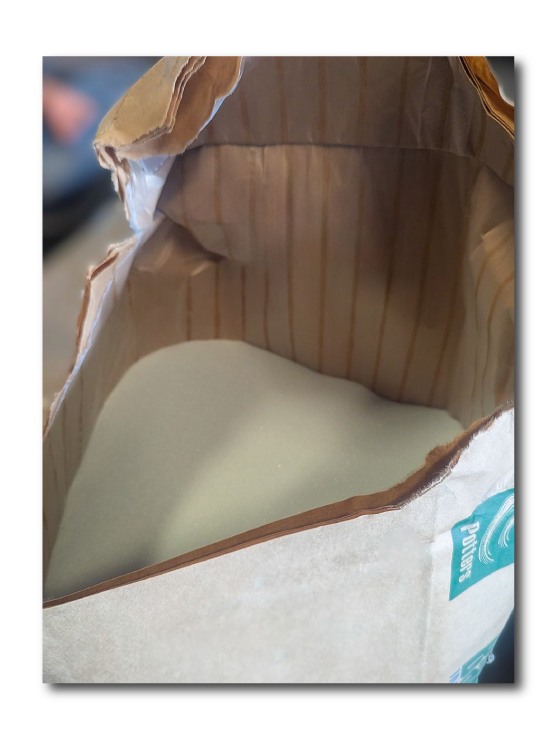

Types of Abrasives: The Dynamic Duo

When it comes to abrasives, not all materials are created equal. Some are gentle artists, while others are heavy-duty wrecking balls (in the best way). Let’s break down the two MVPs of sandblasting here at Body Shop Plus:

Safety First: Don’t Turn Blasting Into a Dusty Disaster

This isn’t something you do in flip-flops while sipping a latte. Safety is critical because high-pressure abrasives + lungs = bad news. Here’s how to stay safe:

- Wear Proper PPE – Respirators, goggles, gloves, and protective suits are non-negotiable.

- Ventilation is Key – Work in a sandblasting booth or use dust collection systems.

- Train Your Team – Only experienced pros should operate the equipment.

- Inspect Gear Regularly – Hoses, nozzles, and compressors need check-ups too.

- Clear Communication – Make sure everyone knows when blasting is happening.

Where Is Sandblasting Used? (Hint: Almost Everywhere)

From restoring vintage cars to prepping ships for battle against the ocean’s wrath, sandblasting has serious range:

- Automotive & Fleet Maintenance – Stripping old paint before a fresh coat.

- Shipbuilding & Marine – Fighting saltwater corrosion like a champ.

- Construction & Concrete – Cleaning graffiti or prepping surfaces.

- Historic Restoration – Bringing old structures back to life.

- Industrial Equipment – Keeping machinery in top shape.

Final Thoughts: Is Sandblasting Right for You?

If you’ve got a surface that needs a serious makeover, industrial sandblasting is one of the fastest, most effective ways to get the job done. Just remember:

- Choose the right abrasive for your project.

- Prioritize safety—no cutting corners.

- Work with professionals if you’re not experienced.

So next time you see a rusty old piece of metal, don’t mourn it—blast it back to life.

Need sandblasting services or equipment? Body Shop Plus has got you covered. Let’s make your surfaces shine (or at least not rust).

Read more about our sandblasting services here: Sandblasting at Body Shop Plus